IP Ratings for Boats and Marine Craft

Ingress Protection (IP) ratings are critical in boat wiring and electrical systems to ensure protection against water, dust, and other environmental factors common in marine environments. These ratings, defined by the International Electrotechnical Commission (IEC) standard 60529, classify the level of protection electrical enclosures, connectors, and equipment have from the intrusion of solid objects and liquids.

Ingress Protection (IP) ratings are critical in boat wiring and electrical systems to ensure protection against water, dust, and other environmental factors common in marine environments. These ratings, defined by the International Electrotechnical Commission (IEC) standard 60529, classify the level of protection electrical enclosures, connectors, and equipment have from the intrusion of solid objects and liquids.

In marine environments, where exposure to water and corrosive salt is a constant challenge, choosing components with appropriate IP ratings is essential for safety and durability.

Understanding IP Ratings

An IP rating typically consists of “IP” followed by two numbers (for example, “IP67”). The first digit represents protection against solid objects (dust, particles). The second digit represents protection against liquids (water, immersion). The higher the number, the greater the level of protection.

the number, the greater the level of protection.

To learn more about how the digits break down, click to enlarge the chart at right.

Critical Areas for IP-Rated Components in Boats

There are four critical areas on a boat that typically require components with higher IP ratings because of exposure to water and the elements.

- Bilge Area: Frequently exposed to water, bilge areas require IP67 or higher-rated electrical components.

- Engine Rooms: Electrical systems in the engine room require protection from humidity, oil, and heat, so IP65 or IP66 is typically recommended.

- Hull Below Waterline: Anything installed below the waterline, such as through-hull fittings or sensors, should have IP68 protection to ensure safety even when submerged.

- Exterior Deck: Any switches, panels, or lighting on the deck need at least IP65, and more often IP67 for spray and immersion protection.

Why IP Ratings are Critical in Marine Electrical Systems

Using products with proper IP ratings plays a critical role in safety. Ingress of water or debris into electrical systems can cause short circuits, fires, or system malfunctions, which is particularly dangerous in a marine environment.

Ingress protection also contributes to durability. Marine conditions (humidity, salt, and water exposure) accelerate corrosion and wear on electrical systems. High IP-rated components reduce maintenance and increase longevity.

There are many other standards and safety regulations such as ABYC, USCG, and IEC. Make sure to check your application’s requirements prior to selecting a component. A component’s certifications are usually listed on their associated datasheet.

How IP Ratings Apply to Boat Wiring and Components

Electrical Enclosures and Connectors. In marine environments, enclosures for electrical components (junction boxes, control panels, battery compartments, etc.) must be protected from water, humidity, and salt spray. Recommended IP ratings are:

- IP65: Suitable for areas exposed to some water splashes, such as engine rooms or above-deck applications.

- IP67: Often used for connectors, junction boxes, or enclosures that may be temporarily submerged or in wet locations, such as bilge pumps or exterior electrical systems.

- IP68: Necessary for components that may be fully submerged, such as underwater lighting, or equipment mounted on the hull below the waterline.

- IP69K: If the equipment or component will be regularly cleaned with high-pressure water jets, or will otherwise be exposed to high-pressure immersion or sprays, an IP69K rating ensures the highest level of protection.

Below: The ecomate® Aquarius™ Series of waterproof connectors from Amphenol Sine Systems provides an IP67/69K waterproof rating along with multiple coupling options and pin counts ranging from 3 to 32 positions.

Cable Glands and Heat Shrink. While cables themselves don’t have an IP rating, cable glands are rated to ensure a watertight seal around wiring. For boats, use IP67 or higher-rated glands in any exposed or critical areas. For connections near waterlines or areas prone to  submersion (like bilges or external equipment), IP68 is advisable.

submersion (like bilges or external equipment), IP68 is advisable.

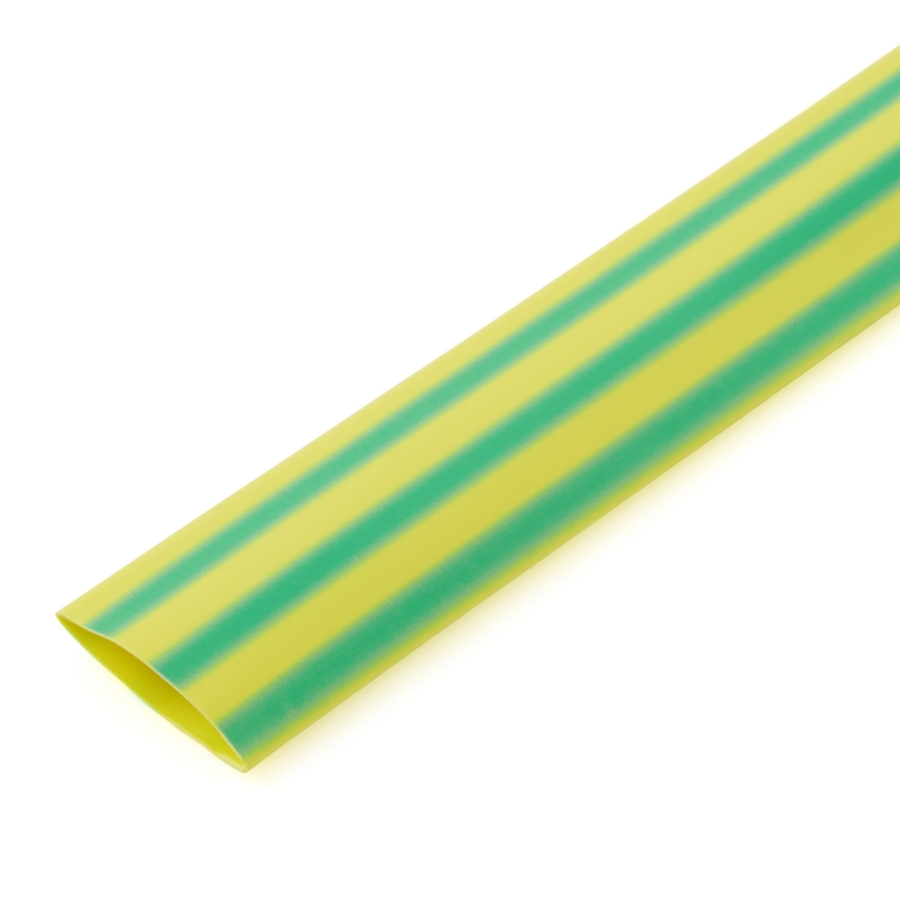

Heat shrink is another effective way to seal cables and connections. Although IP ratings typically don’t apply to heat shrink, make sure any heat shrink you use is flame retardant and rated highly by organizations such as UL, SAE, or ASTM.

Right: Green and yellow colored heat shrink from DSG-Canusa is ideal for sealing ground wire and terminals in marine applications.

Switches, Controls, and Instruments. Exposed components such as switches and control panels on boats (especially those on the deck) need high levels of protection against both dust and water. IP67 or IP68 rated switches should be used for deck installations, where they are exposed to rain, sea spray, or immersion during cleaning or bad weather.

deck installations, where they are exposed to rain, sea spray, or immersion during cleaning or bad weather.

Right: IP67-rated AH Series anti-vandal switches from CIT Relay and Switch come with pre-attached wire leads for an extra-tight seal against water intrusion.

Lighting Fixtures. Marine navigation lights, deck lights, and underwater lights must also be IP-rated for their specific environment. IP67 is suitable for deck lighting and navigation lights exposed to splashes. IP68 is required for underwater lighting.

Below: An IP67-rated panel-mount LED indicator light made by Switch Components.

Battery Compartments and Electrical Panels. Components located in engine rooms or other internal spaces that are subject to moisture should also be IP65 or IP66 rated to prevent moisture and condensation from affecting the system’s integrity.

Enclosures protecting sensitive electronics, such as navigation systems or control modules, may need to be IP66 or IP67 rated for added protection against water ingress in rough seas or during vessel cleaning.

Right: An IP66-rated Series 53 battery disconnect switch with a built-in circuit breaker, made by Mechanical products. This product was designed with marine applications in mind.

Conclusion

Using appropriately rated IP components for boat wiring and electrical systems is essential to ensure safety, performance, and compliance in marine environments. High IP-rated components help protect against corrosion, water ingress, and damage, which is critical in the harsh conditions boats often operate in.

When selecting electrical components for marine use, also be sure to comply with marine electrical standards such as those set by the ABYC or the IMO. Learn more in the article Electrical Standards for Marine Wiring.

Subscribe Now

Subscribe and be the first to know when new articles are published.