Battery Isolators 101

Battery isolators are a foundational component in many multi-battery vehicle electrical systems. Wherever a vehicle must both guarantee reliable engine starting and support auxiliary electrical loads, isolators play a critical role in managing power flow, protecting batteries, and ensuring system stability. While the underlying concept is simple—keep batteries separated when needed and connected when appropriate—the technology has evolved significantly alongside modern charging systems and vehicle electronics.

Battery isolators are a foundational component in many multi-battery vehicle electrical systems. Wherever a vehicle must both guarantee reliable engine starting and support auxiliary electrical loads, isolators play a critical role in managing power flow, protecting batteries, and ensuring system stability. While the underlying concept is simple—keep batteries separated when needed and connected when appropriate—the technology has evolved significantly alongside modern charging systems and vehicle electronics.

What Is a Battery Isolator?

A battery isolator is a device that allows multiple batteries in a vehicle to be charged from a single power source—typically an alternator—while preventing those batteries from discharging into one another when the engine is off or system voltage drops. Most commonly, isolators are used to separate a starting battery from one or more auxiliary (house, accessory, or implement) batteries.

The key objective is protection: ensuring that loads connected to auxiliary batteries cannot drain the starting battery and leave the vehicle unable to start. At the same time, the isolator must allow efficient charging of all batteries when a charging source is present.

Why Battery Isolators Are Important

In vehicles with only a starting battery and minimal electrical load, isolation is unnecessary. However, modern vehicles and mobile equipment increasingly power radios, lighting, refrigeration, hydraulics, inverters, telemetry, and control systems that operate independently of engine runtime. Without proper isolation, these loads can unintentionally discharge the starting battery, causing downtime, service calls, or safety risks.

Battery isolators also improve battery longevity. Different batteries may experience different duty cycles, depths of discharge, and charge acceptance. Preventing uncontrolled current flow between batteries reduces stress, minimizes imbalance, and supports predictable charging behavior.

How Battery Isolators Work

At a functional level, a battery isolator sits between the charging source and multiple batteries, controlling when electrical connection is allowed. When charging voltage is present and conditions are appropriate, the isolator connects batteries so they can be charged. When charging stops or voltage falls below a defined level, the isolator separates them.

The difference between isolator types lies in how that connection decision is made and how current is routed. Some isolators rely on passive components, while others use active control logic and switching devices.

Traditional Battery Isolators

Diode-Based Isolators

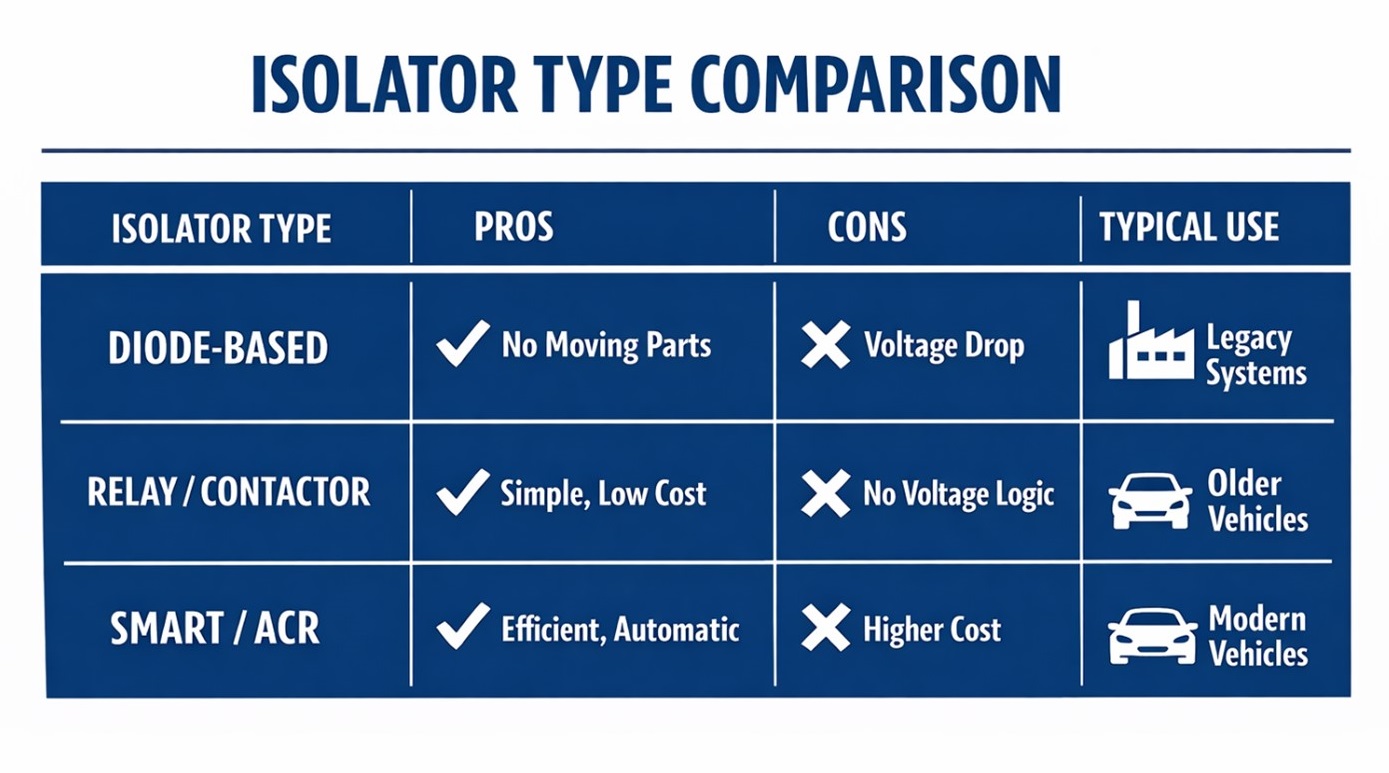

One traditional type of battery isolator uses high-current diodes to direct charging current to multiple batteries while preventing reverse current flow. Diode-based isolators are electrically simple and have no moving parts. They are ideal for simple, rugged multi-battery systems where reliability, electrical simplicity, and continuous isolation are prioritized over maximum charging efficiency (there is typically a 0.5 to 0.7 voltage drop across diodes). They are well suited for applications with fixed-output alternators, modest electrical loads, and battery chemistries tolerant of reduced charging voltage, and they perform well in harsh, vibration-prone environments.

Another traditional approach uses a high-current relay or solenoid to physically connect batteries when energized. These systems are often triggered by ignition power, oil pressure switches, or alternator excitation circuits. While relay isolators avoid diode voltage losses, they are essentially binary devices: on when triggered, off when not. They do not account for battery state of charge, voltage levels, or charging priority.

The Evolution to “Smart” Battery Isolators

As vehicle charging systems and electrical loads have become more complex, isolators have evolved to include voltage sensing and logic-based control. Modern “smart” battery isolators combine a heavy-duty relay with electronic monitoring that continuously evaluates system voltage.

Instead of relying on an ignition signal, smart isolators wait until the primary battery reaches a defined charging voltage that indicates charging is available before connecting auxiliary batteries. When system voltage drops below a lower threshold, they automatically disconnect, preserving the starting battery. This voltage-based approach aligns more closely with actual battery state and charging conditions rather than assumptions about engine operation.

Smart isolators also eliminate diode voltage losses, making full alternator output available to connected batteries. Many smart isolators are designed to support bi-directional charging, allowing auxiliary batteries to feed the starting battery when charged from shore power, solar, or external chargers.

Right: A smart battery isolator from Cole Hersee. “Smart” battery isolators make decisions based on measured battery voltage rather than a simple on/off trigger.

Compatibility with Modern Charging Systems

One of the most significant drivers behind smart isolator adoption is the rise of variable-output and ECU-controlled alternators. These systems adjust output voltage dynamically based on load, temperature, and fuel economy targets. Traditional ignition-triggered isolators can behave unpredictably in these environments, connecting batteries when charging is insufficient or disconnecting during brief voltage dips.

Voltage-sensing smart isolators are inherently more compatible with these systems because they respond to actual electrical conditions rather than assumed operating states. This makes them well-suited for late-model vehicles, mixed battery chemistries, and complex auxiliary power architectures.

Common Real-World Applications

Marine Applications

Boats often have dedicated engine-start batteries and separate house banks powering navigation, lighting, pumps, and electronics. Battery isolators ensure the engine battery remains protected while allowing all banks to charge from alternators or shore power systems. Corrosion resistance and reliability are especially critical in this environment.

Recreational Vehicles

RVs typically use isolators to separate chassis batteries from house batteries that support living systems such as lighting, refrigeration, HVAC controls, and inverters. Smart isolators are increasingly favored due to their compatibility with solar charging, converters, and modern alternator systems.

Agricultural Equipment

Tractors, harvesters, and sprayers often operate high-current electrical systems for implements, guidance systems, and control modules. Isolators help manage multiple batteries and prevent auxiliary loads from interfering with engine starting, particularly in cold-weather or seasonal-use scenarios.

Work Trucks and Fleet Vehicles

Service vehicles commonly power lifts, compressors, radios, and idle-reduction equipment. Battery isolators allow these loads to operate without risking vehicle downtime, while still ensuring batteries recharge efficiently during operation.

Specialty and Off-Road Vehicles

Emergency vehicles, expedition rigs, and off-road equipment frequently run extensive auxiliary electronics. In these applications, smart isolators provide automatic control without requiring operator intervention, improving reliability in demanding conditions.

Key Selection Considerations

When selecting a battery isolator, current capacity, voltage thresholds, environmental rating, and compatibility with the charging system must be considered. Battery chemistry, expected duty cycle, and the presence of external charging sources also influence isolator choice. While traditional isolators may still be suitable for simple systems, smart isolators offer clear advantages in efficiency, protection, and adaptability.

Conclusion

Battery isolators are essential components in modern vehicle electrical systems that use multiple batteries. From early diode-based designs to today’s voltage-sensing smart isolators, the technology has evolved to meet increasing electrical demands and more sophisticated charging systems. Understanding how isolators work–and choosing the right type for the application-helps ensure reliable starting, efficient charging, and long-term battery health across a wide range of vehicle and equipment platforms.

For related information on protecting multi-battery systems, see:

- How to Choose Between Battery Isolators and Separators

- Battery Isolators and Automatic Charging Relays: A Comparison

- Equalizers in Dual Voltage Systems: What and Why

Subscribe Now

Subscribe and be the first to know when new articles are published.