How to Choose Between Automotive Cross-Link and GPT Wire

There are many types of low-voltage automotive wire, but the two most common are GPT wire and cross-link polyethylene wire. The key differences between them lie primarily in the properties of their insulating jackets. Here’s an overview.

GPT Wire

GPT wire is general circuit wiring designed for standard electrical usage in vehicles. GPT stands for “General Purpose Thermoplastic” in reference to the jacket around the wire. The PVC insulation jacket is heated and extruded through a die and onto a bare copper wire, serving as insulation that can accept up to about 60 volts and withstand temperatures from -45°C (-49°F) to +85°C (185°F).

Less expensive than cross-link, GPT wire is typically found in under-the-hood or in-the-cabin applications. Its heat and liquid-resistant capabilities are not as robust as cross-link wire; thus GPT wire should not be used next to the engine or in places exposed to liquids or the outdoor elements.

Cross-Link Wire

Cross-link automotive wire is more durable and better suited for extreme conditions compared to GPT wire. It is also more expensive.

Cross-linked insulation is created by extruding the material through a tube, under heat and pressure, to “cross-link” or change the molecules of insulation to another state. Cross-link polyethylene wire is rated for temperatures between -51°C (-60°F) and +125°C (257°F) and can also handle up to 60 volts. It is also resistant to moisture, grease, oil, gasoline and most acids.

Cross-link is commonly used in heavy-duty applications requiring wire that can take a beating, such as fuse blocks inside engine compartments, and in electrical systems more likely to be exposed to open air and the elements. Cross-link wire is also recommended over GPT wire for applications that require adherence to SAE guidelines.

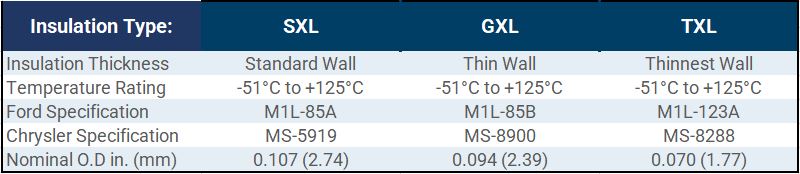

There are three different types of cross-link wire, which are classified by insulation wall thickness. All three are ideal for automotive applications that require reliability in both high heat and extreme cold.

- SXL insulation is the thickest cross link type, making it the most abrasion resistant. SXL insulated wire is durable for under the vehicle or equipment exposed to the elements. It is often the preferred choice in higher-stress applications such as engine compartments. If you’re looking for extra durability, SXL is a good choice.

- GXL insulation is thinner than SXL, but still tough enough for under the hood. It is used mainly for trucks and trailers, primarily in engine compartments. The thinner insulation makes it lighter, more flexible, and less expensive than SXL.

- TXL insulation has an ultra-thin wall. It is thinner than GXL, but still durable enough for under-the-hood use. A major benefit of TXL insulation is its flexibility and ease of use—it takes up less space and is easy to slide through tight compartments.

Below is a reference chart for help in selecting from these three types of cross-link automotive wire.

In summary, cross-link wire withstands greater temperature ranges and environmental exposure than GPT wire. But for many automotive applications, less expensive GPT wire will be more than adequate. To get started stocking your fleet with the right wire, view all our wire and cable products.

Both cross-link and GPT wire come in many colors and spool sizes. Custom wire printing and striping is available from Waytek to help easily identify wires for future maintenance—for more information, call our customer service at 800-328-2724.

Subscribe Now

Subscribe and be the first to know when new articles are published.