Best Practices for Using Automotive Connectors

Automotive electrical connectors play a critical role in the overall functionality and safety of vehicles. Given their importance, it's imperative to employ best practices in their use, installation, and maintenance.

Drawing on insights from the webinar "Automotive Electrical Connectors—A Comprehensive Exploration" by Waytek and Amphenol Sine Systems, this article delves into essential guidelines to ensure safety and efficiency in the use of automotive electrical connectors.

Correct Connector Wiring

To avoid short circuits or incorrect signal transmission, make sure that the wiring matches the connector’s pin assignments. Utilize tools (such as crimping tools) recommended by the connector manufacturer to ensure solid connections. Learn more in How to Choose the Right Crimping Tools and How to Crimp Wires.

Power Down for Safety

Before making or breaking connections, make sure to power down systems and isolate them from the power source. This precautionary step may seem obvious, but if overlooked it poses a risk of electrical shock or damage to the vehicle’s electrical system.

Proper Connector Installation and Mounting

Always follow manufacturer’s guidelines when installing a connector. Ensure the proper tightening of any mechanical fasteners to prevent unintentional disconnections. Make sure that connectors are mounted in a location that minimizes exposure to heat, moisture, and mechanical stress—or utilize connectors that are IP rated to withstand such conditions.

Connector Polarization and Keying

Utilize the built-in polarization or keying features of the connector to prevent incorrect mating, which can damage the connector or the connected equipment.

Right: Examples of keyed wedgelocks from Amphenol Sine Systems A Series connectors.

Connector Labeling

Label connectors for easy identification and maintenance. Using connectors with colored housings for color-coded identification can help in quickly recognizing connections, simplifying maintenance tasks.

Routing and Organization of Connectors and Wiring

Route wires and connectors away from moving parts, sharp edges, and hot surfaces to prevent damage and ensure longevity. Use cable ties, clamps, electrical wiring tape and looms to bundle and organize wires neatly, reducing the risk of chafing and electrical interference.

Connector Strain Relief

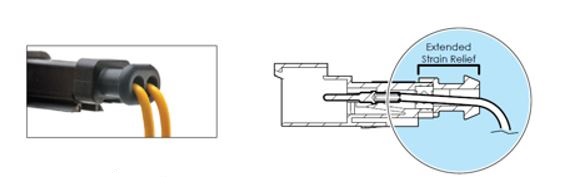

Ensure that cables are supported or clamped to prevent strain on the connector and the wiring. Strain can lead to premature wear or unintentional disconnection. Consider using connectors with built-in strain relief features.

Below: A connector from Amphenol Sine Systems with extended strain relief built in to protect each wire cavity and maximize sealing integrity.

Don’t Exceed Connector Ratings

Never exceed the current or voltage ratings of the connector. Staying within the ratings ensures the safety and reliability of the electrical system. Exceeding them can lead to overheating, reduced lifespan, or even potential fires.

Connector Testing and Inspection

After installation, thoroughly test electrical connections using a multimeter (shown at right) or continuity tester to verify proper continuity, voltage, and resistance. Periodically inspect connectors for any signs of damage, corrosion, or loose connections, and perform maintenance as needed.

Stay Updated on Connector Specifications

Regularly check the connector manufacturer’s datasheet or guidelines for any updates or changes to connector specifications.

Conclusion

By following these best practices, you can ensure your electrical connectors are installed correctly for use, resulting in reliable and safe electrical connections within the vehicle.

To learn more about choosing and installing automotive connectors, see the webinar Automotive Electrical Connectors—A Comprehensive Exploration, now available on demand. Also explore the industry-leading A Series™ Family of Connectors from Amphenol Sine Systems now available and in stock at Waytek.

Subscribe Now

Subscribe and be the first to know when new articles are published.