Automotive Wire 101: The Basics

Unless you've been repairing or wiring 12-volt equipment for a long time, the world of automotive wiring can be daunting. You’ll need to understand some jargon and technical terms to get started. To ensure you're getting the right wire for the job, here's an essential overview of what you need to know.

Wire Size/Gauge

Wire size is measured by gauge, and it’s the opposite of what newcomers might think: The thicker the wire, the smaller it’s corresponding gauge number. For example, 8-gauge wire is thicker than 20-gauge wire. The gauge you need will depend on the current draw of the circuit and the wire length between the circuit and the power source.

If you're purchasing for repairs, make a point of having the technical manuals for any tractors, equipment, and other vehicles you service handy. The manual often lays out exactly what gauge of wires are used for which components, so you'll be able to keep the necessary wires in stock.

Also keep in mind that wire of 8 gauge or thicker is typically referred to as “cable.”

Amperage

Next up is the "load" a wire can take, which is expressed in amperes, often shortened to "amps." Amperage or amps tell you the total amount of electricity that can flow through the wire. You should know the current rating of every wire in your shop and ensure that it's clearly labeled. Overloading a wire is dangerous for both your staff and your customers; a wire with the wrong current rating can short out, stalling equipment in dangerous locations, damaging important systems, and even starting fires in extreme cases. Know your amps, and always double-check that the automotive wire you're ordering can take the load.

Check to see what relays, fuses, circuit breakers, and other overload protection your wiring project requires, and similarly make sure you know what connectors will be used for the work. Too many amps can short out connectors, too.

The Basic Formula for Amps, Gauge, and Wire Length .jpg)

As a rule, the longer your wire needs to be run for the application—and the more power that needs to flow through it—the lower the gauge (i.e., the greater the thickness) required. It's generally recommended to err on the side of thicker wire where possible. Our article on The Two Things to Double-Check When Sizing Battery Cables includes a handy amp and gauge chart for your reference.

Materials: Copper and Aluminum

Automotive wire is available in two main materials: copper or aluminum. Copper is more conductive, flexible, and less likely to corrode than aluminum; however copper weighs more and is prone to price fluctuations, so you’ll need a good distributor to keep your costs low. Aluminum, by contrast, is lighter and cheaper, but less durable and more likely to corrode or develop electrical resistance over time. Most automotive applications use copper wire.

Automotive wire is generally coated with either general purpose thermoplastic (also called GPT or PVC) or cross-link insulation, so named because the insulation material is extruded under heat and pressure, changing the molecular structure and allowing it to withstand higher temperatures. GPT insulation is more cost-efficient, while cross-link insulation is more durable and heat resistant.

As a rule, look at how the wire is being used. Applications that are likely to face extreme high temperatures like engine compartments should use cross-link wire; general in-the-cabin applications can use GPT/PVC-insulated wire.

Cross-link insulated wire comes in three different types, classified by insulation wall thickness. For more details, and to see a chart for selecting cross-link wire types including Ford and Chrysler specifications, see our article How to Choose between Automotive Cross-Link and GPT Wire.

Twisted Pair Cable for CAN Bus Applications

If you are working with automotive CAN bus wiring, be sure to familiarize yourself with twisted pair cable in its shielded and unshielded varieties, which are essential for preventing electromagnetic interference with signals transmitted through the CAN bus system.

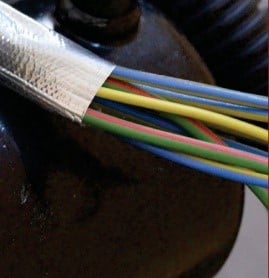

Wire Coloring, Striping and Printing

Automotive wire is available in colors across the spectrum. One of the best ways to make common repair and construction jobs easier is to assign a different color for each type of automotive wire according to its end use.

Colors are used often to identify and trace a wire to a corresponding circuit. Tractor trailers, for example, use a standard color scheme – brown wire signifying left light, yellow signifying right light, and so on. Many market segments have their own standard wire coloring systems. For example, see wire color-coding standards in the marine industry.

use a standard color scheme – brown wire signifying left light, yellow signifying right light, and so on. Many market segments have their own standard wire coloring systems. For example, see wire color-coding standards in the marine industry.

A further way to expand on your color scheme is to add a color stripe. For even more clarity you can order printed wording that tells exactly what the wire is for. Most wire suppliers will be able to perform customer striping and printing; it's something you should consider for busy shops and product development. Being able to sort wire quickly allows you to be more efficient in construction and repairs, and lets you quickly access and replenish the wire you're using the most of. It'll also allow you to color-code common tasks involving wiring, freeing up more experienced employees to deal with more complicated tasks.

Connections

Wiring generally utilizes two types of connections: soldered and solderless.

Soldering is time-consuming and prone to error and, with the wide array of solderless connectors available, is considered obsolete for most automotive wiring today. Many wire and connector manufacturers discourage soldering due to the difficulty of ensuring quality control during the process.

Solderless connections have become the fastest and easiest way to terminate wires. They involve the use of commonly available automotive wire connectors such as spade terminals, ring terminals and quick disconnects. Learning how to make a proper crimp is essential for many of these products. Solderless connections may not be durable enough for all applications. However, you can equip yourself with additional strain relief products such as heat shrink or vinyl tape to ensure the longevity of solderless connections.

Learn More

If you have any questions about wire, call Waytek. We're happy to answer your questions and can guide you towards the best product for your use. If you're looking for the best in automotive wire, view our wire and cable products.

Subscribe Now

Subscribe and be the first to know when new articles are published.